East to West self-rotating PV structure, programmed to avoid inter raw shadow effects, programmed to capture diffused light & to self-position at extreme weather condition are called Single-axis controlled Tracker.

After years of global OEM supply experience of key tracker parts & Design involvements, We are offering a well competitive, Maintenance free, Qualitative & sturdy trackers for small to large projects. Our trackers are FEA & CFD analysed + rigorously tested for life expectancy & sturdiness. Our indigenously manufactured each Tracker parts & control unit are made to compete the large international players in terms of reliability & after sales need. We achieve economy of supply through scale of integrated single location production facility.

Aro-elastic wind instability analysis by CFD Modeling

| Type of Structure | Independent Row – Horizontal Single axis Tracker |

| Module Architecture | 1p & 2p |

| Module Type | Bifacial & all framed modules |

| Tilt angles | +60° to -60° (Optional +50° to -50°) |

| Tilt Angle Variation(N-S) | +/-2° -along the length of the table |

| Ground coverage ratio | 30%-60%-Flexible configurable design |

| Table Length | 30-134 modules in Row |

| Module edge distance from ground | >500 mm |

| Operating temperature | -10°c to 65°c |

| Corrosion class supply | C2/C3/C4 – as per ISO 1294 |

| Structure type | Bolted Structure with Serrated lock nuts |

| Wind resistance | In operation – at any angle; up to 20m/s (70km/h) In Stow position – at 0° ;up to 50m/s (180/km/hr) |

| Tracker Stowing time | < 6 min(accelerated drive algorithm) |

| Structural Material | HDG & Galvalume coated steels Grade S235/S355 |

| Faster Material | High tensile grade 8.8 Fasteners with Zinc-Flake coatings |

| Column Profile | >160mm / 260mm size Sigma Plus – Profile |

| Column Foundation type | Concrete piled / concrete pad / Ramming |

| Column Foundation depth | Designed based on soil test reports & on-site pull-out tests |

| Flood-safe height | >800mm from ground level |

| Earthquake resistant | Yes-With Seismic Dampers(optional) |

| Drive Mechanical Parts | IP55W – Dust & weather proof |

| Drive Actuators lubrication | Re-lubrication every 5 Years |

| Drive Actuators tested | for > 40 years of life at 2x higher load |

| Drive type | Self-locking Synchronized screw driven actuator system |

| Drive Actuators per Module | 12-24 configuration based on site architecture & location |

| Drive Actuators per column | On every column / on multiple column per table |

| Power requirement | 24V DC with battery back-up for 2 days / 5 days |

| Software used | Mechanical (FEA) & Wind CFD analysis |

| Regulations | As per ASCE 7-10, IS 875, IS 800/801 & EURO Code |

| Practical tests carried | -Head Bearing life test – 50 Years -Drive actuator life test – 40 Years -Drive actuator tensile test – 5000MPA -Drive tube torsion test – 100N -Complete table accelerated life test – 40 Years -Turbulent Wind load stress on drive actuators – 25000N |

| Wind Tunnel Aeroelastic Test | Not required – locking at short table length |

| Drive Algorithm | Astronomical formulas with angle feedback |

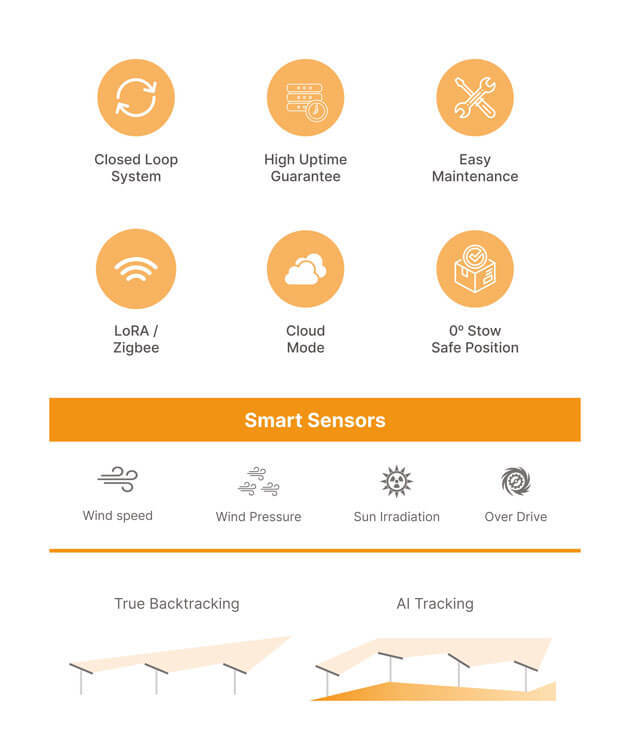

| Backtracking | Individual Row or Terrain based – To avoid shadow effects |

| Diffuse Light Capture | Light cloud & Heavy cloud mode |

| Control options for | Cleaning mode:+/- 60° |

| Individual table / entire plant | maintenance mode / safe mode: 0° |

| Individual table / entire plant | maintenance mode / safe mode: 0° Emergency stop mode : at actual position |

| Control Box & Electrical Parts | IP55w/IP65w – Dust & Weather proof |

| Sensors | |

| Communication | Wireless low power network- LoRa |

Lubrication of actuators & gearboxes

| North – South | +/- 40 mm |

| East – West | +/- 30mm |

| Height Tolerance | +/- 40mm |

| Pile Tilt | +/- 3° |

| Pile Twist | +/- 5° |

| Ground Slope | +/- 150 mm |

| Head bearing Unit | Pre-assembled & Tested |

| Drive actuator Unit | Pre-assembled & Tested |

| Drive tube support bearings | Pre-assembled |

| On site Work | Pre-assembled |

| Control Unit | Pre-Programmed for each row & site; On site calibration |

| Installation Guide line | Free Training at Rajkot or Supervised at additional cost |

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |