Quality Control

We are a Young & dedicated team of quality controllers.

Involvement of our Quality team starts from Order exhaustion planning stage upto final dispatch. i.e. The Raw material purchase would be made based on our detailed raw material requirements & only from our trusted suppliers. The material dispatch clearance would be granted only after quality approvals.

Inspection Equipment

- 3-D measurement arm size 2000 mm

- 3-D measurement with CMM Mitutoyo (External service)

- 2-D measurement with Digital Mitutoyo Height Master Type: LH-600

- Surface Plates of various sizes

- Mitutoyo Verniers & Micrometers (0-200mm)

- Bore & Depth Gauges (0-300mm)

- Height Comparator

- ID & OD Comparator

- Slip Gauges

- ID & OD Thread Gauges

- Various Gauge Masters

- Surface Roughness Comparators

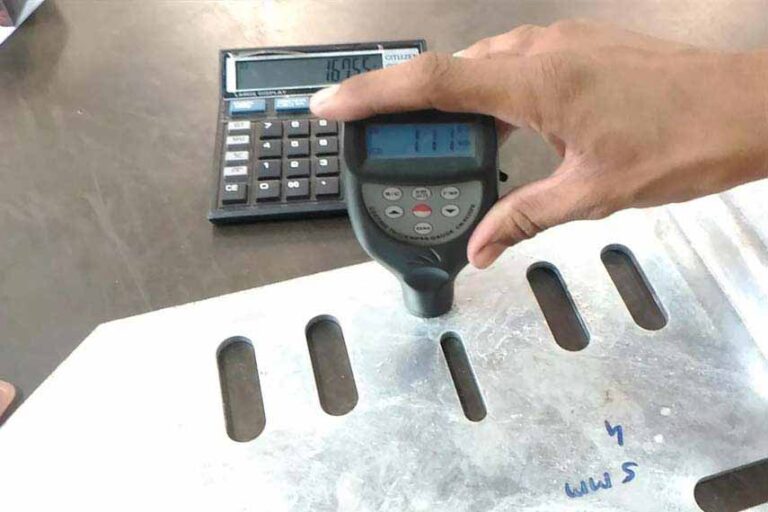

- Surface coating thickness measuring Gauge

- Salt spray test chamber as per ISO 9227 or ASTM B117

Our Own Strict Quality Procedures

- To Check & approve every incoming material

- To supply & maintain track record of 3.1 certificates for every article

- In process, quality check while manufacturing & frequent prob batch quality check

- Quality check for non-dimensional parameters like Burrs, Optical view, surface damages, Plating thickness etc

Raw Material Inspection

- Chemical Composition Analysis

- Mechanical Tastings: Tensile Test, Hardness Test, Impact Test, Proof load test etc

- Corrosion tests as per ASTM A262, ASTM G36, G35, A761 Specifications

- Liquid Penetrant or Dye Penetrant Inspection

- Ultrasonic crack detection